Customization Options for HSS Tubes

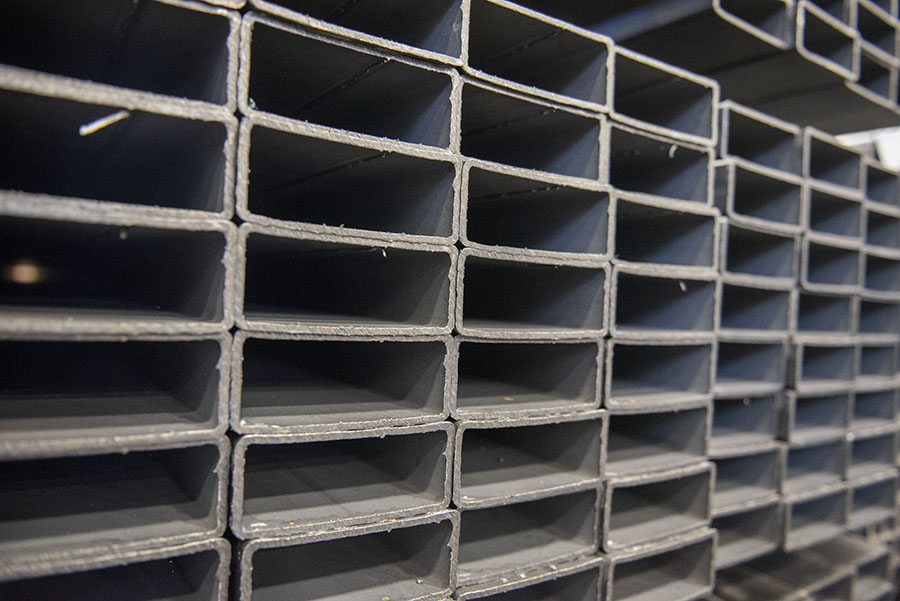

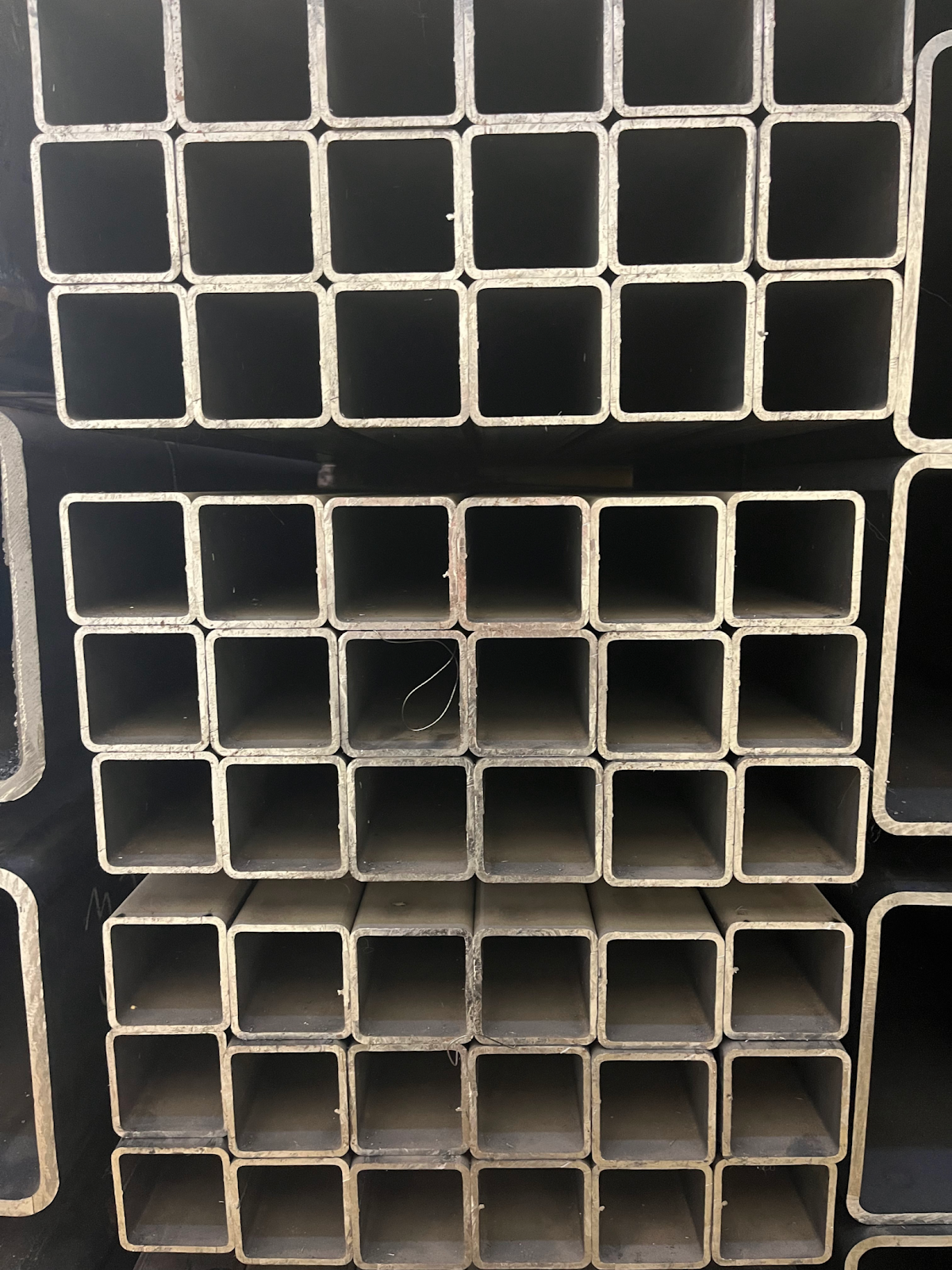

Hollow Structural Sections (HSS) tubes offer extensive customization options to meet the diverse needs of engineering and architectural projects. These options include:

The inclusion of square HSS and square jumbo tubing is particularly beneficial for projects requiring uniform geometries across multiple cross-sections, ensuring a consistent look and performance. Customizing HSS tubes, including A513 mechanical tube and A500 hollow structural section tube, can significantly optimize their integration into specific design plans or structural requirements.

Personalizing Your HSS Structural Steel Tube

Personalizing your HSS structural steel tube involves selecting the right dimensions, steel grade, and surface finish to meet your project’s unique specifications. By customizing these factors, you can ensure that your HSS tube offers optimal performance, durability, and aesthetic appeal, making it a valuable asset in your construction or engineering project.

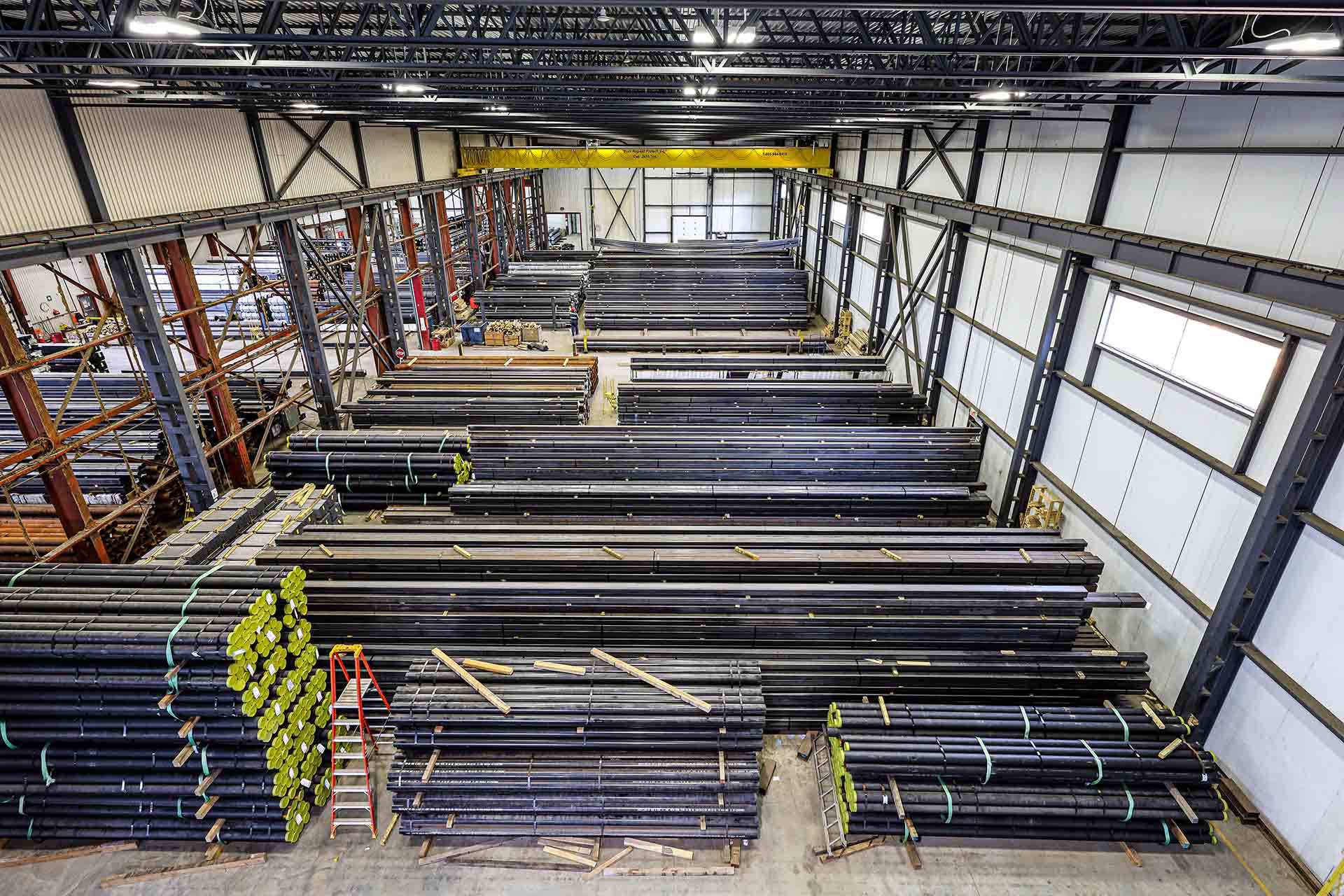

At Altitube Steel, we offer a comprehensive range of customization options for HSS tubes, including:

Size and Dimensions: Choose from a variety of standard and non-standard sizes to match your project’s specific requirements.

Steel Grade: Select the appropriate steel grade based on factors such as load-bearing capacity, environmental conditions, and project specifications.

Surface Finish: Customize the surface finish of your HSS tube to enhance its corrosion resistance, aesthetics, and longevity.

End Treatment: Opt for specific end treatments such as beveling, threading, or swaging to facilitate easier installation and compatibility with other components.

Cutting and Fabrication: Take advantage of precision cutting and fabrication services to achieve exact dimensions and shapes for seamless integration into your project.