ASTM A500 PDF

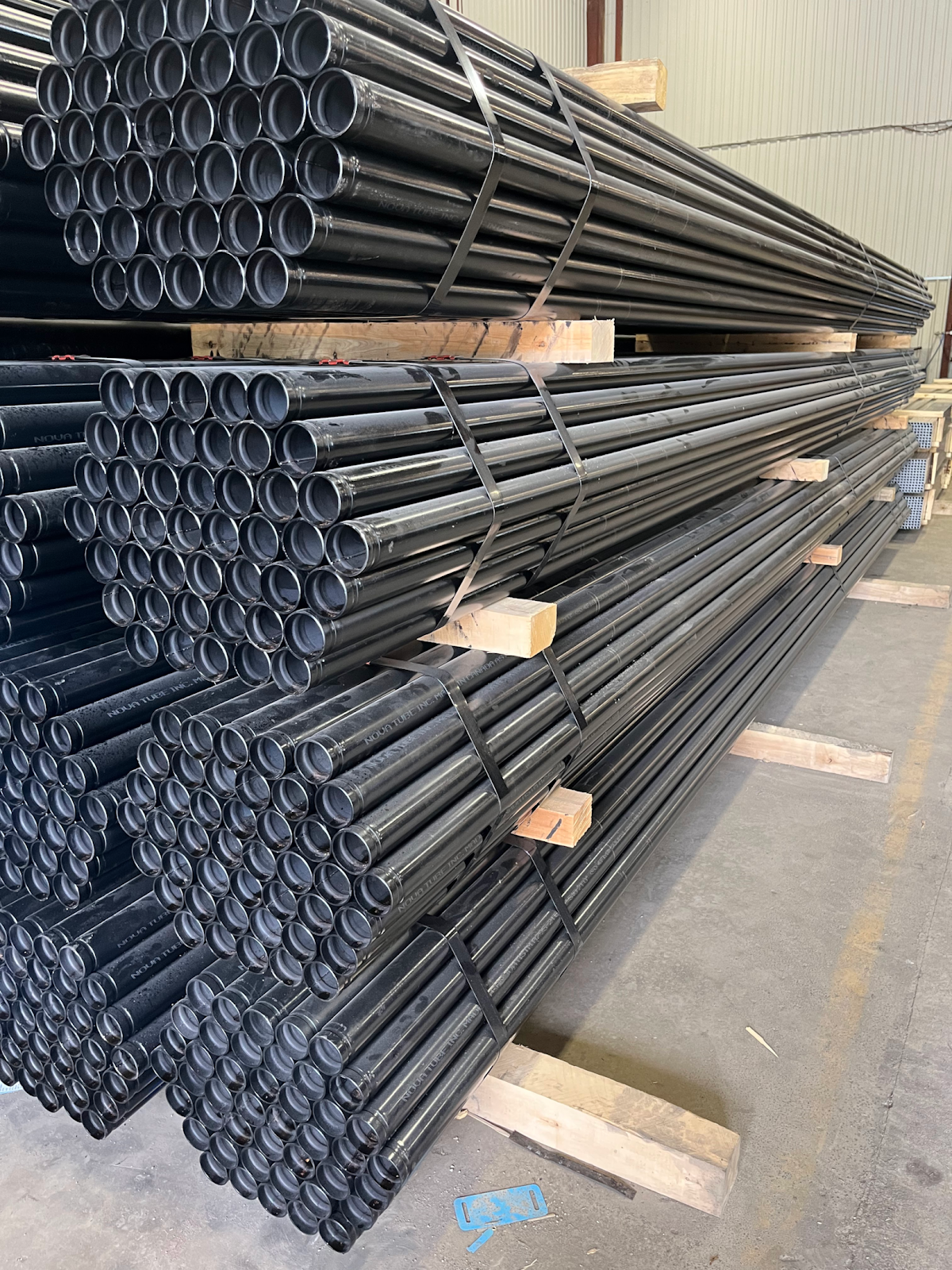

ASTM A500 is a comprehensive standard specification for cold-formed welded and seamless carbon steel structural tubing. This specification encompasses round, square, rectangular, and special shape structural tubing, making it versatile for various construction applications. Whether for welded, riveted, or bolted construction of bridges and buildings, ASTM A500 tubing provides the necessary strength and stability. The tubing is available in both welded and seamless forms, with a periphery of up to 88 inches (2235 mm) and a specified wall thickness of up to 1.000 inch (25.4 mm). Notably, Grade D tubing requires heat treatment to meet the stringent standards set forth in this specification. This ensures that the tubing can withstand the demands of structural applications, providing reliable performance in diverse environments. ASTM A500 graded tubes are the most common and widely used in North America.