Key Features of Industrial Piping Systems

Service Offering

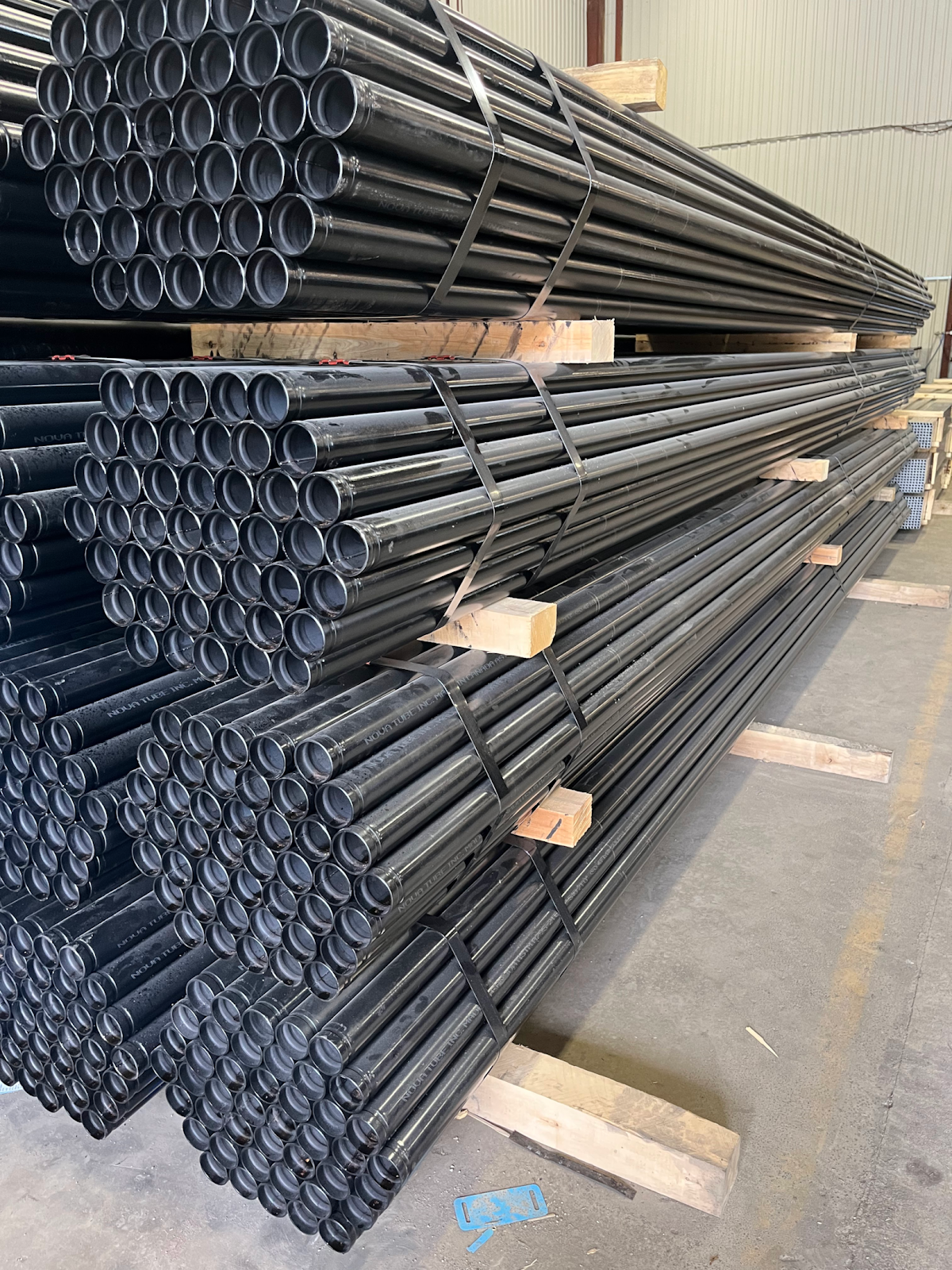

We are a reliable and precise steel pipe distributor. You can count on us for your projects. As a key player in industrial piping distribution across Quebec, we ensure that your needs are met with the highest standards of quality and service. We have inventory in stock, which you can easily pick up during the day or in the evening with our night shift, or you can request a delivery.

Altitube Steel offers you a range of Schedule 10 and Schedule 40 industrial piping for all your projects. As a high-volume steel distributor, we can assist you with managing your steel pipes. We also offer just-in-time delivery for your projects or storage options for larger projects that require better delivery management.

Durability

Industrial piping are engineered to endure tough conditions, handling high pressures and extreme temperatures. This robustness aims to ensure long-term reliability and minimal maintenance needs.

Comprehensive

Support from initial consultation to ongoing maintenance service, our team provides comprehensive support. We offer expert advice, troubleshooting, and regular maintenance services to help keep your piping systems in peak condition.

Environmental Responsibility

Modern piping systems are designed with environmental considerations in mind. They prioritize the use of sustainable materials and efficient designs that aim to reduce waste and energy consumption, contributing to greener industrial operations.